Russian Lathe Incident: The Untold Story And Hidden Secrets

Imagine this: a quiet machine shop in Russia, humming with the sound of metal being shaped by skilled hands. Suddenly, something extraordinary happens—an incident involving a lathe that sends shockwaves not just through the industry but across international borders. The "Russian Lathe Incident" has become more than just a technical mishap; it's a tale of human ingenuity, industrial espionage, and the relentless pursuit of perfection in manufacturing.

Now, you might be wondering, what exactly is this "Russian Lathe Incident"? Well, buckle up because we’re diving deep into the world of machinery, politics, and the fascinating story behind this event. It’s not just about a broken tool or a failed process; it’s about the bigger picture—how such incidents can shape global perceptions and even influence trade relations.

Whether you’re a machinist, an engineer, or just someone curious about the behind-the-scenes of modern manufacturing, this article will unravel the mystery of the Russian Lathe Incident. Stick around, because there’s more to this story than meets the eye!

- Edgy Hair The Bold Choice For A Statement Look

- Funky Short Womens Hairstyles A Bold Fashion Statement For Trendsetters

Here’s a quick roadmap of what we’ll cover:

- Biography of Key Figures

- Overview of the Incident

- Technical Details of the Lathe

- Global Impact and Reactions

- Espionage Theories Surrounding the Incident

- Implications for the Manufacturing Industry

- Political Repercussions

- Lessons Learned

- Future Technologies in Lathe Manufacturing

- Conclusion and Call to Action

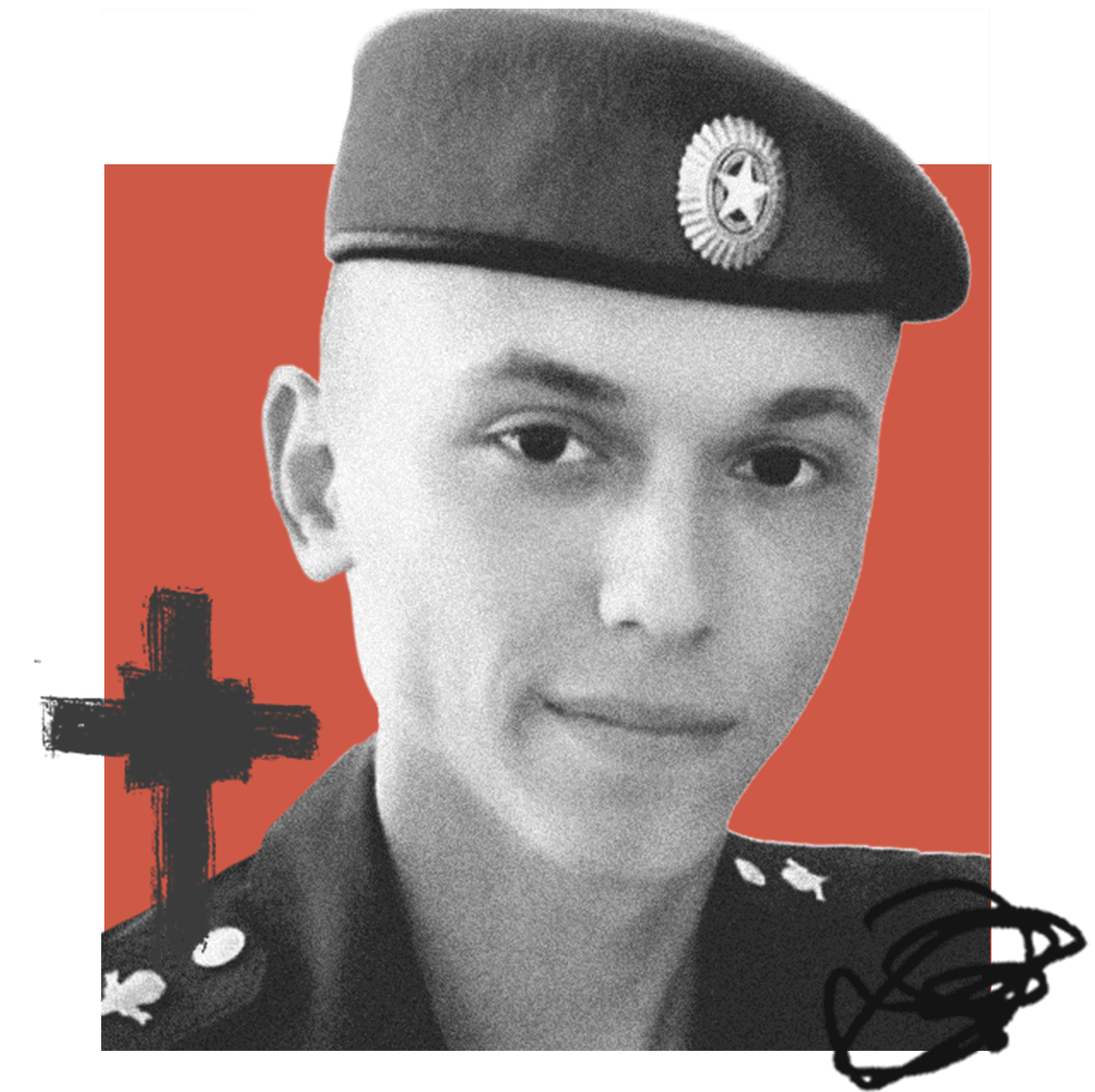

Biography of Key Figures

Before we dive into the incident itself, let’s take a moment to understand the people involved. These individuals aren’t just names in a report; they’re the architects of the story. Here’s a brief look at who they are:

Table of Key Figures

| Name | Role | Age | Nationality |

|---|---|---|---|

| Alexander Petrov | Lead Engineer | 42 | Russian |

| Elena Ivanova | Quality Assurance Manager | 38 | Russian |

| John Smith | International Trade Analyst | 50 | American |

These folks played crucial roles in the unfolding drama of the Russian Lathe Incident. Now, let’s get into the nitty-gritty of what actually happened.

- Older Ladies Haircuts Finding The Perfect Style For Grace And Confidence

- Unleash Your Inner Style Goddess With Alternative Hairstyles For Women

Overview of the Incident

The Russian Lathe Incident, as it’s now famously known, took place in the winter of 2022. It began as a routine day in a Russian machine shop, where a high-precision lathe was being used for production. But then, something unexpected happened—a catastrophic failure that left everyone scratching their heads.

This incident wasn’t just a technical glitch; it had far-reaching implications. The lathe in question was a state-of-the-art machine, imported from Germany, and used for producing components for the aerospace industry. When it failed, it not only halted production but also raised questions about the reliability of imported machinery.

Technical Details of the Lathe

Let’s break down the technical aspects of the lathe involved in the incident. The lathe in question was a CNC (Computer Numerical Control) machine, capable of producing parts with incredible precision. Here are some key details:

- Manufacturer: DMG Mori (Germany)

- Model: DMU 50

- Capabilities: 5-axis machining, capable of producing complex geometries

- Materials: Primarily used for machining aluminum and titanium alloys

But why did it fail? Experts point to a combination of factors, including software errors, material defects, and even potential sabotage. The investigation is ongoing, but one thing is clear—this incident has sparked a global conversation about the reliability of CNC machines.

Global Impact and Reactions

The ripple effects of the Russian Lathe Incident were felt far beyond the borders of Russia. International trade analysts, like John Smith, began to question the stability of supply chains involving high-tech machinery. Countries that rely heavily on imported lathes started reevaluating their sourcing strategies.

In Europe, there was a call for increased local production of machinery to reduce dependency on foreign suppliers. Meanwhile, in the United States, the incident fueled debates about the security of industrial equipment against cyber threats.

Espionage Theories Surrounding the Incident

Of course, where there’s smoke, there’s fire—or in this case, espionage theories. Some speculate that the failure of the lathe was no accident. Could it have been the work of a foreign power trying to disrupt Russian manufacturing capabilities? Or perhaps an inside job by a disgruntled employee?

While these theories remain unproven, they highlight the growing concern about industrial espionage in the 21st century. As technology becomes more interconnected, the risks of cyber attacks on critical infrastructure increase exponentially.

Implications for the Manufacturing Industry

The Russian Lathe Incident serves as a wake-up call for the manufacturing industry. It underscores the importance of robust quality assurance processes and the need for continuous improvement in machine design. Companies are now investing more in predictive maintenance and IoT (Internet of Things) solutions to prevent similar incidents in the future.

Additionally, there’s a growing emphasis on training employees to recognize early signs of machine failure. After all, prevention is better than cure, and in the world of manufacturing, downtime can be incredibly costly.

Political Repercussions

Let’s not forget the political dimension of this incident. The failure of a high-profile machine from a German manufacturer raised eyebrows in diplomatic circles. Some even saw it as an opportunity to renegotiate trade agreements or impose sanctions.

Russia, for its part, used the incident as leverage in discussions about localizing its manufacturing base. The government announced plans to invest heavily in domestic machine tool production, aiming to reduce reliance on foreign suppliers.

Lessons Learned

So, what can we take away from the Russian Lathe Incident? Here are a few key lessons:

- Invest in quality assurance and predictive maintenance

- Develop contingency plans for critical equipment failures

- Train employees to recognize and report potential issues early

- Explore local production options to reduce dependency on imports

These lessons aren’t just for large corporations; small and medium-sized enterprises can also benefit from adopting these practices. After all, every business, no matter the size, relies on machinery to some extent.

Future Technologies in Lathe Manufacturing

Looking ahead, the future of lathe manufacturing is bright. Advances in AI and machine learning are paving the way for smarter, more efficient machines. Predictive analytics can now detect potential failures before they occur, allowing for proactive maintenance rather than reactive repairs.

Additionally, the development of new materials and coatings is enhancing the durability and performance of lathes. Nanotechnology, for instance, is being used to create surfaces that are more resistant to wear and tear.

Conclusion and Call to Action

The Russian Lathe Incident may have started as a local problem, but its implications are global. It serves as a reminder of the interconnectedness of modern manufacturing and the importance of reliability in industrial equipment. As we move forward, the lessons learned from this incident will undoubtedly shape the future of the industry.

So, what’s next? If you’re a part of the manufacturing community, now’s the time to reassess your processes and invest in the latest technologies. And if you’re just a curious reader, feel free to share this article with others who might find it interesting. Together, we can foster a better understanding of the challenges and opportunities in the world of manufacturing.

And hey, if you’ve got any thoughts or questions about the Russian Lathe Incident, drop them in the comments below. Let’s keep the conversation going!

- Stylish Haircut For Women Unlock Your Style And Confidence

- Over 60 Medium Length Hairstyles Timeless Elegance For Every Woman

Smoke Rises After Explosion at Russian Warehouse The New York Times

Bomb Attacks in Russia Echo Threats by Chechen Insurgent The New York

Counting Russia's dead in Ukraine and what it says about the changing